CellMat Laboratory is fully equipped for the production, characterization and modelling of the micro and macroscopic properties of cellular materials.

Labs and

equipment

1. Production and sample preparation laboratory

This laboratory section is equipped with the devices typically used for the transformation of plastic materials but at a lab-scale. This equipment can be used for the production of foamed materials and also for the manufacturing solid parts.

| DEVICE | MODEL |

| Internal mixer attached to a rheometer | Rheodrive 5000, Haake |

| Twin screw extruder attached to a rheometer | Rheodrive 5000, Haake |

| Two roll mill | DW5110, Fanyuan |

| Co-rotating twin screw extruder | ZK 25 T Teachline, Collin |

| Single screw extruder with chill roll | CR 72 T Teachline, Collin |

| Micro-injection molding machine | 6/10P, BabyPlast |

| High-pressure vessel (up to 400 bar) | Parr 4681, Parr Instruments Company |

| Pressure vessel (up to 100 bar) | Talleres Remtex |

| Low-temperature pressure vessel (up to 200 bar) | Parr 4760, Parr Instruments Company |

| High-pressure stirred reactor | Parr 4544, Parr Instruments Company |

| Hot/cold plates hydraulic press | Talleres Remtex |

| Hot plates hydraulic press with accurate control | Talleres Remtex |

| Molds and tools for the production of parts under pressure | CellMat Laboratory & Talleres Remtex |

| 3D Printer | Dimabox 3D printer, Dima 3D |

| Ultrasound dispersive tip | VCX-750, Sonics Vibra-Cell |

| Low-shear fluid mixing machine | Eurostar Power Control-visc P1, IKA |

| High-shear fluid mixing machine | T 25 Digital Ultra Turrax, IKA |

| Ball mill | Ball Mill, Orto Alresa |

| Mixer mill | MM 400, Retsch |

| Precision cutter machine | IsoMet 1000, Buehler |

| Polishing machine | LaboPol-2, Struers |

| Band sawing machine | CY 135, Tronzadoras MG |

| High temperature oven | 2001405, JP Selecta |

| Electric muffle furnace | Select-Horn, JP Selecta |

| Digital vacuum drying oven | VacioTem TV, JP Selecta |

| Vacuum drying oven | VacioTem T, JP Selecta |

| Drying oven | E-42, Heraeus |

| Test tube shaker | Multi Reax, Heidolph |

| Vortex mixer | ZX3, Velp |

| Platform shaker | Vibramax 100, Heidolph |

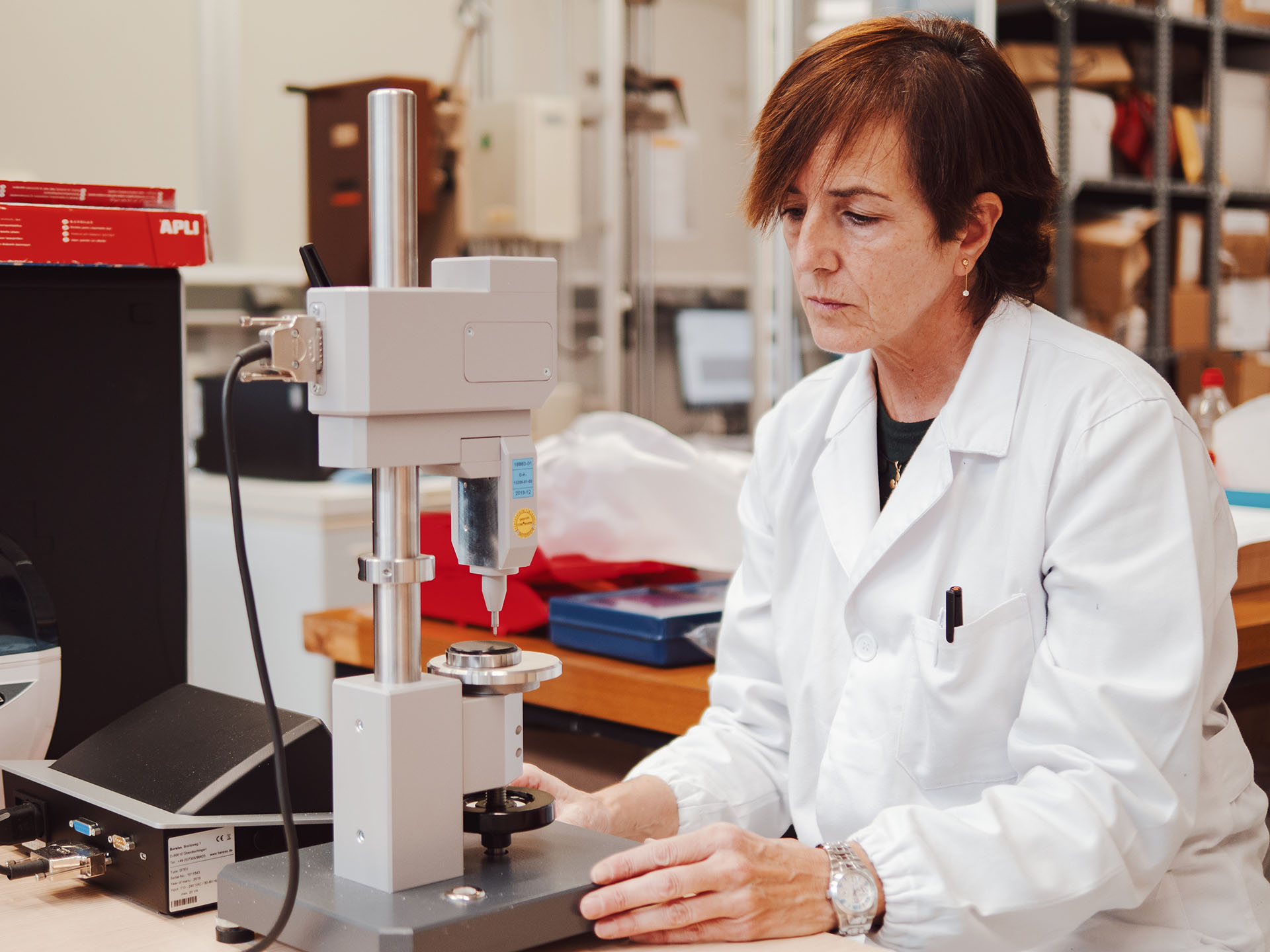

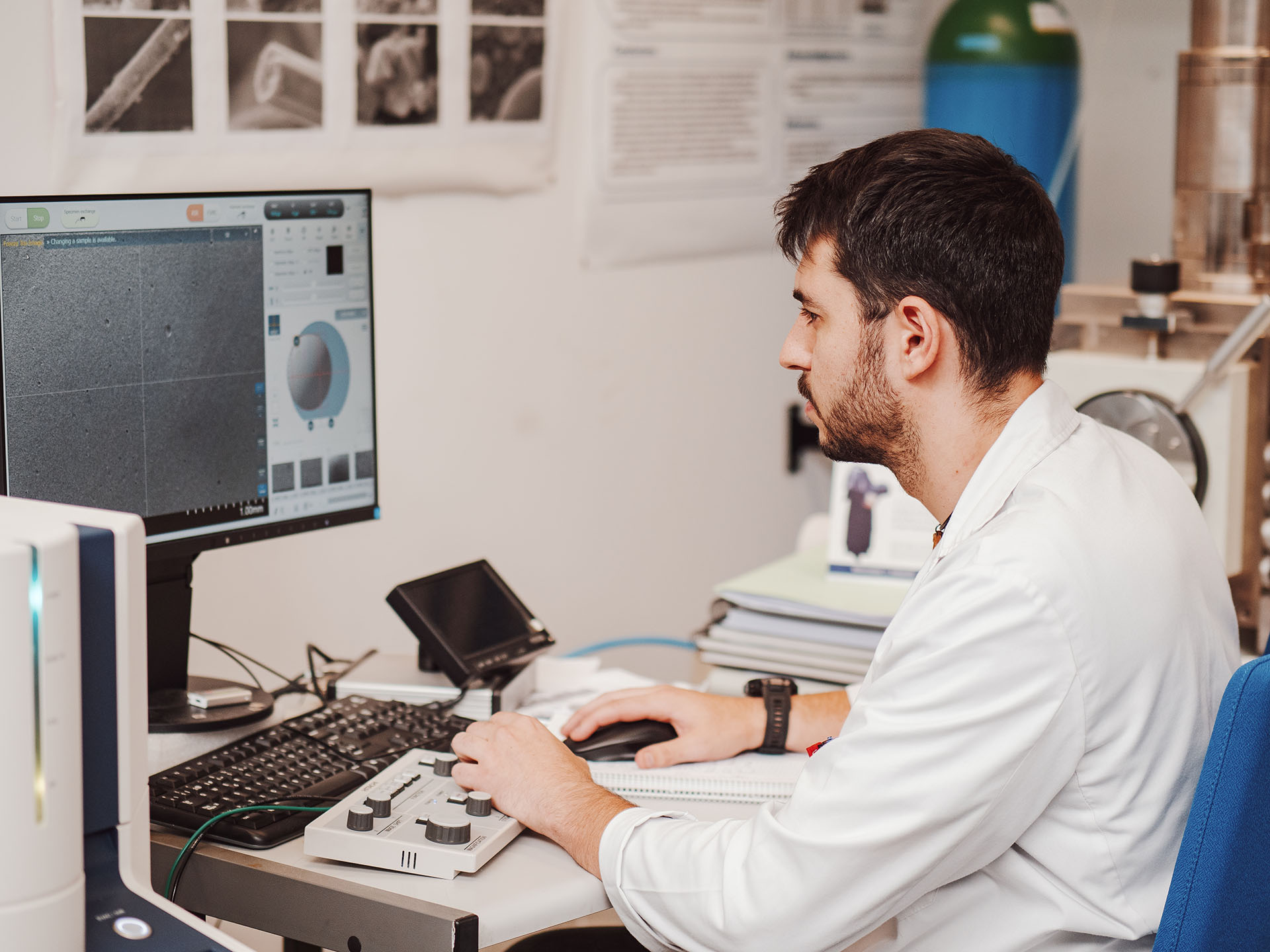

2. Microscopic and macroscopic characterization laboratory

The equipment included in this area of the Laboratory is aimed at the characterization of both the microstructure and the physical properties of the polymeric based solid and cellular materials.

| DEVICE | MODEL |

| CHEMICAL-STRUCTURAL PROPERTIES | |

| Fourier Transform Infrared spectrometers (FTIR) | · Tensor 27, Bruker |

| · Alpha, Bruker | |

| Ultra-Violet spectrometer | UV-2102 PC, Shimadzu |

| Energy-dispersive X-ray spectrometer (EDX) | QX 200, Link |

| Polarized light optical microscope with a digital camera | · Microscope: DM2500 M, Leica |

| · Camera: EC3, Leica | |

| Scanning electron microscope (SEM) | FlexSEM 1000, Hitachi |

| Air pycnometer | P1.86, EijKelKamp |

| Gas pycnometer | AccuPyc II 1340, Micromeritics |

| Volumetric titration | Karl Fischer V10, Mettler |

| PH meter | FiveEasy F20-Std, Mettler |

| THERMAL PROPERTIES | |

| HDT/VICAT device | VHDT-3, Metrotec |

| Thermogravimetric Analyzer (TGA) | TGA/SDTA 861, Mettler |

| Differential Scanning Calorimeter (DSC) | DSC 3+, Mettler |

| Thermo-Mechanical Analyzer (TMA) | DMA/TMA 7, PerkinElmer |

| Melt flow tester (MFI & VFI) | · Twelve Index, Atsfaar |

| · MF20, Ceast-Instron | |

| Rotational viscometer | Rotavisc LO-VI Complete, IKA |

| Stress controlled rheometer: Shear rheology | · Shear rheology fixture: EHP, TA Instruments |

| · Rheometer: AR 2000 EX, TA Instruments | |

| Stress controlled rheometer: Extensional rheology | · Extensional rheology fixture: SER 2, Xpansion Instruments |

| · Rheometer: AR 2000 EX, TA Instruments | |

| Thermal Conductivimeters – Stationary Method | · Rapid K, Holometrix |

| · Fox 314, TA Instruments | |

| Thermal Conductivimeter – Transient Plane Source Method | HDMD, Hot Disk |

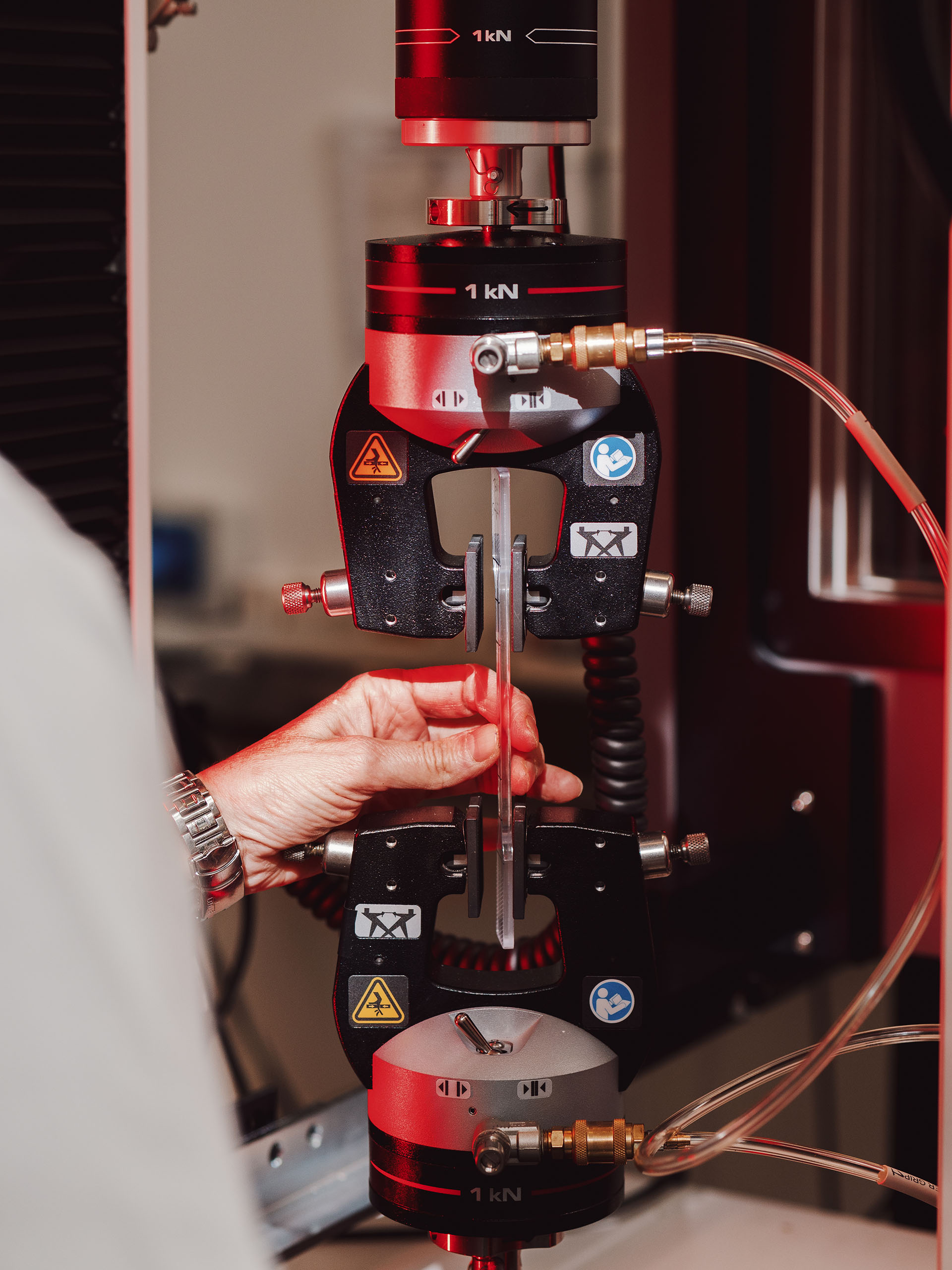

| MECHANICAL PROPERTIES | |

| Universal testing machine | · 5.500R6025, Instron |

| · Tensile test | · 3369, Instron |

| · Compression test | |

| · Bending test | |

| · Temperature chamber (-100 ºC – 350 ºC) | |

| · Video extensometer | |

| Dynamic mechanical Analyzer (DMA) | · DMA-861e, Metler |

| · DMA-7, Perkin-Elmer | |

| · DMA-8000, Perkin-Elmer | |

| Hardness tester: Shore A, Shore O, Shore D, Shore OO | · U/72, Bareiss |

| · Digi Test II (BS09), Bareis | |

| Vickers micro-durometer | MHO IB, Zeiss |

| Charpy and Izod impact tester | · 53566, Frank |

| · 53304, Frank | |

| Falling dart impact testing machine equipped with a high speed acquisition camera | · Impact tester: DT-50/1200, Microtest |

| · Registration camera: MV-D1024-160, PhotoFocus | |

| Creep and recovery test machine | Mod.DF5, Microtest |

| ACOUSTIC PROPERTIES | |

| Impedance tube | Ua-1630, Bruel and Kjaer |

| FIRE RESISTANCE PERFORMANCE | |

| Limiting Oxygen Index equipment (LOI) | Oxygen indez, FTTT |

| Calorimetric bomb | 131EE, Parr |

3. Foaming mechanisms laboratory

This laboratory is specifically focused on the analysis (qualitative and quantitative) of the physical mechanisms involved in foaming processes.

- Pressure vessel with internal vision – Designed by CellMat Laboratory

- Optical expandometry meter – Designed by CellMat Laboratory

- X-ray radioscopy and tomography equipment – Designed by CellMat Laboratory

- Infrared camera – HotFind L, SDS Infrared

4. Laboratory for properties simulation

The last section of CellMat Laboratory aims to predict the behavior of complex polymeric systems by using simple or complex analytical models and finite element modelling (FEM)

-

- Work stations: 8 cores – 32 Gb RAM; 48 cores – 96 Gb RAM.

- FEM software (ANSYS)

- Other software: Matlab; Mathematica.

We can help you

What research or innovation do you need?