Polyurethane foams are by far the most popular cellular polymers as they cover more than the half of the total foams market. Depending on if they are either rigid or flexible they are mainly employed as thermal insulators (rigid polyurethane foams) or for comfort related applications (mattresses, seats) in the case of flexible foams. The production of polyurethane foams is based on the reactive mixing of polyol and isocyanate. The comprehension of all the aspects related with the formation and performance of these materials is far to be simple and it motivated the creation of this research topic in CellMat Laboratory.

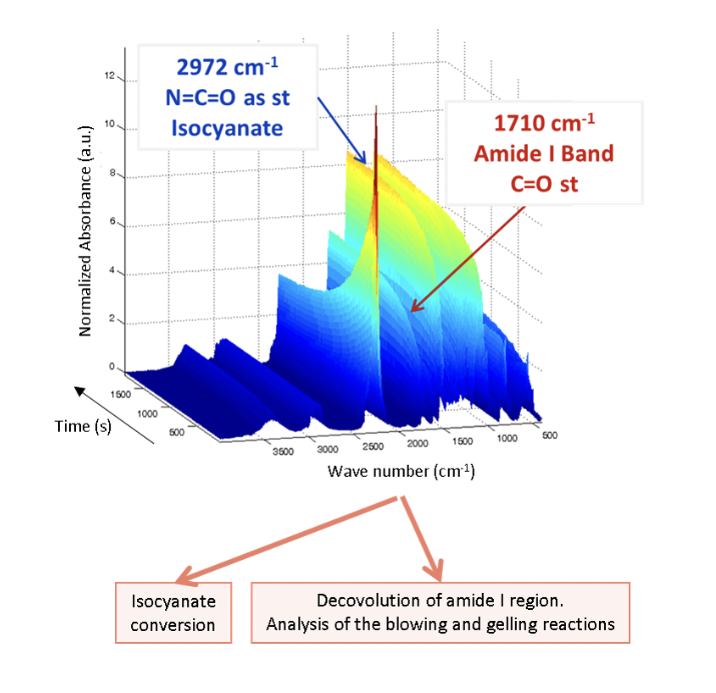

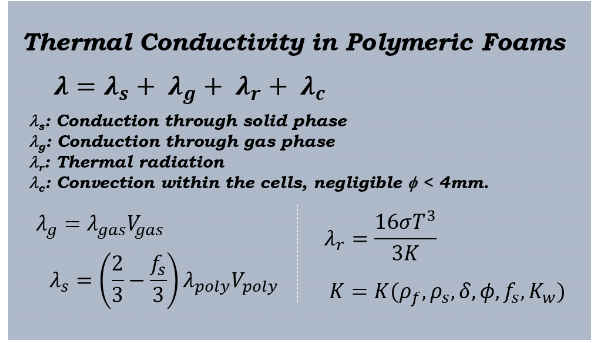

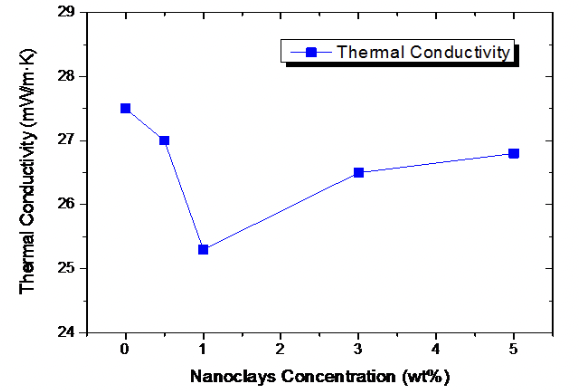

CellMat Laboratory works in the different aspects involved in the production, characterization and modelling of polyurethane (either rigid or flexible) foams. A methodology based on the combination of in-situ (X-ray radioscopy and FTIR) and ex-situ (tomography and scanning electron microscopy) experimental techniques has been extremely helpful to disentangle the complex reactions and processes occurring during the formation of this kind of foams. The analysis of the reaction kinetics and the characterization of the structure and the properties of polyurethane foams has been the basis to develop formulations with tailored characteristics.